Water based polyurethane adhesive for laminating seamless liner cloth

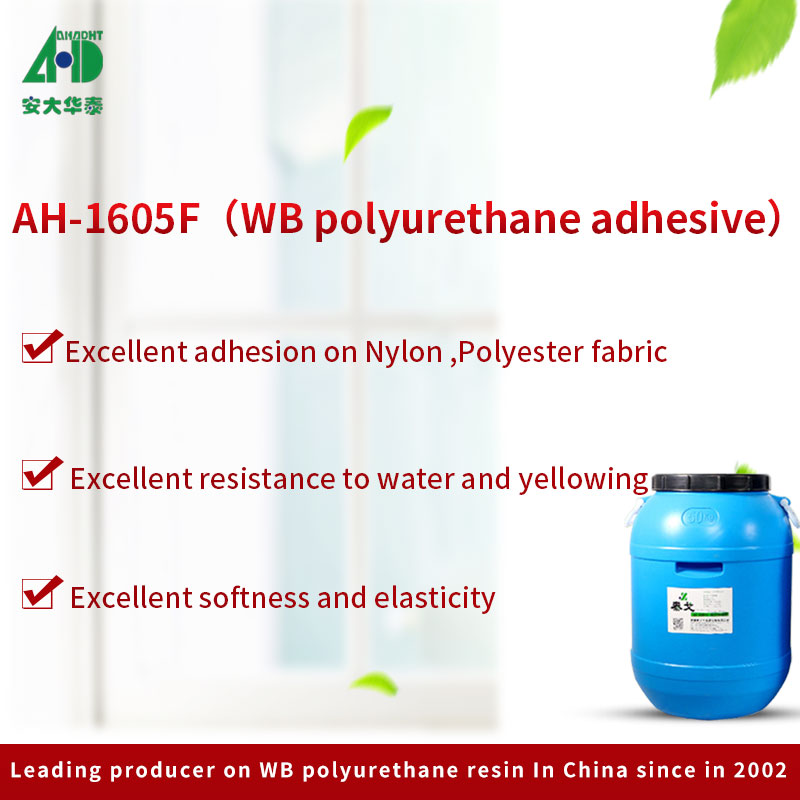

Water based polyurethane adhesive(AH-1605F) for laminating seamless liner cloth

In traditional down jacket production, Gall bladder for down garments uses commonly is process of needle and thread is sewed, however,fluff drills out from pinhole extremely easily.This is a great damage to the anti - down treatment of the liner cloth, so in recent years the new use of polyurethane adhesive to make seamless liner cloth,completely improve the leakage velvet .This kind of adhesive is a kind of water-based environmental polyurethane adhesive, can be precoated on the liner cloth, hot pressing can be carried out when the down jacket production, faster and efficient than the traditional needle sewing, more efficient.This seamless liner composite process is being adopted by more and more cloth factories.

The following is our process how to use the water polyurethane adhesive and performance on the liner cloth:

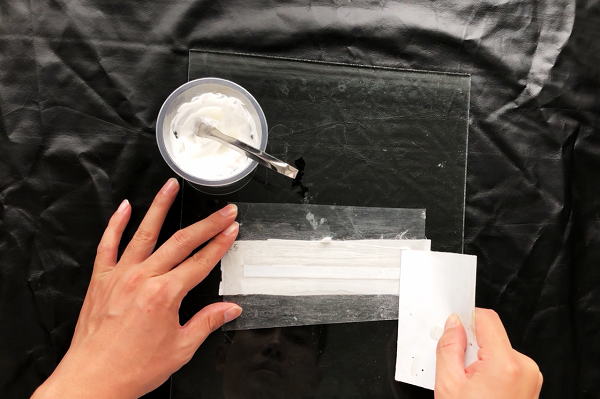

1. Coating on the liner cloth. Blade coating the prepared adhesvie onto the liner cloth, the width

of which is about 5mm

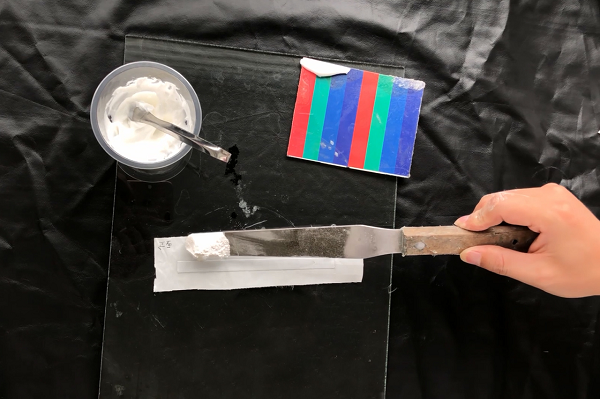

2. Spraying the powder.Hot melt powder on the coated strip, remove excess hot melt powder

3. Drying..Put in oven at 80℃ for 10min4. Heat pressing.Thermal pressure 130℃, about 10-13 seconds

5. Peeling strength test.The peel was performed after 10min of natural cooling.As a results,Peeling strength average 10.79n, the highest 12.53n, adhesive stays on the white liner cloth;)

6. Water immersion experiment.The average wet peel strength of 50 hours of soaking water is

≥6N

7. In Conclusion,After the test, the bonding strength of adhesive(AH-1605F) can reach more than

10N, after the test of soaking water in the wet state can still reach more than 6N strength, is a kind

of high-quality environmental protection water adhesive

评论

发表评论